Stone Is it better to have longer lines?

The stone decoration and decoration of buildings are spread all over the world, from high-end buildings, municipal squares, banks and other places, to small residential areas, which seem to have a close and intricate relationship with stone products. The stone decoration and decoration of buildings use various stone products for decoration. Among the stone products, the amount of engineering boards is the highest, followed by various shapes of stone lines. The lines of door frames, ceiling lines, baseboards, and other lines are everywhere and always reflect in our eyes.

The decoration of buildings with lines makes them more enchanting, beautiful, and colorful. If engineering boards are compared to good flowers, then the lines are green leaves. It is precisely with the contrast of lines and green leaves that the stone engineering board emits a dazzling brilliance and radiance.

Although stone lines add color to buildings, excessive pursuit of decorative effects in line design may lead to deformation and breakage of the lines, seriously affecting the decorative effect of the lines. The design of linear products should be scientific and based on the theory of mechanics. However, the design of stone products may not necessarily be reasonable due to the designer’s lack of mechanical theory knowledge.

We often see that the lines of stone are designed to be long and large, while others are designed to be long and narrow, which is incorrect from the perspective of mechanical theory. The design of lines should consider both the strength and deflection of the stone in order to be correct and reasonable.

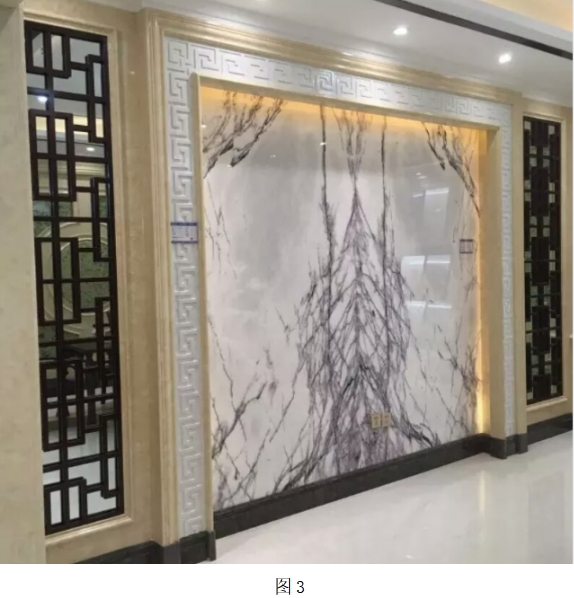

Figures 1 to 5 show the application of lines in architectural decoration. Figure 1: Application of lines in exterior wall decoration; The lines in Figures 2 and 3 are applied to the decoration of the background wall; The lines in Figures 5 and 6 are used for the decoration of the door frame. From the 5 figures, it can be seen that the length of the lines is very long, involving the issue of dividing the length of the lines.

If the line segmentation is reasonable, the line will not deform or break. If the segmentation is not appropriate, it is easy to cause the line to deform or break if it is too long. If the line segments are too short and there are too many installation gaps, it will affect the decorative effect of the building. Therefore, the reasonable segmentation of lines is important and should be highly valued.

“

01

The mechanical theoretical basis of line design

σ=(3F * L)/(2b * h * h)

F – Failure load (i.e. bearing capacity); L – span; B – width; H – thickness.

From the above formula, it can be inferred that as the length of the line increases, σ becomes larger for the same cross-sectional area. As σ increases, the lines are more prone to bending. When σ is greater than the bending strength of the stone itself, the line will break.

The calculation formula for deflection under single load is f=- FL3/(48EI), where I=bh3/12 and E is the elastic modulus of the stone.

The formula above indicates that the longer the L of a line, the easier it is for lines with the same cross-section to bend. When the deflection reaches the allowable limit of the stone itself, the line will break.

The above two formulas are the mechanical theoretical basis for designers to design line lengths.

“

02

The relationship between line length, thickness, strength, and deflection

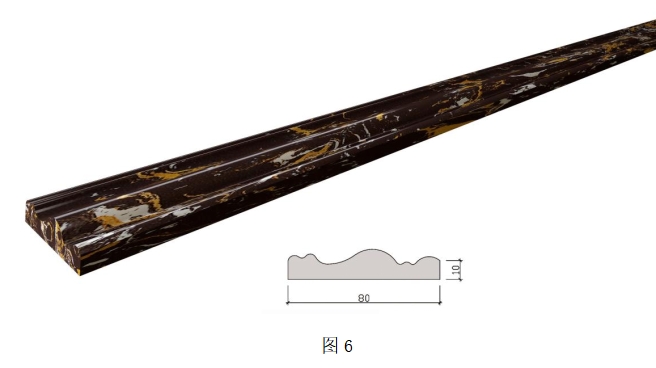

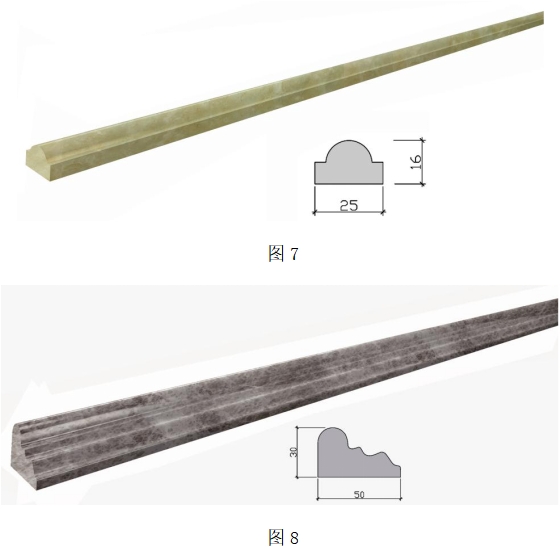

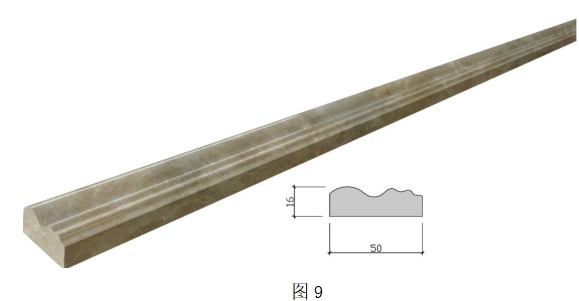

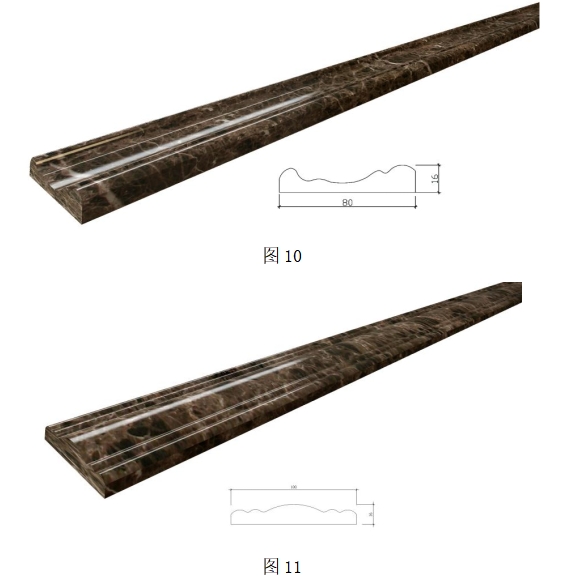

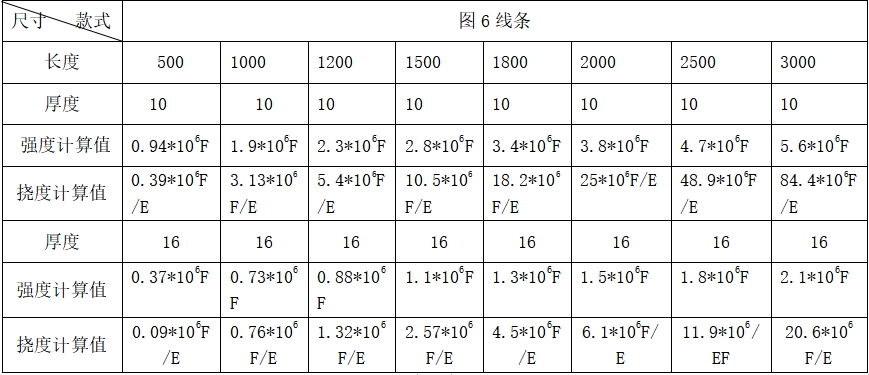

Figures 6 to 11 show several granite lines processed by a certain stone making and processing enterprise. It can be seen from the figures that the lines are long in length and thin in thickness. For many years, artificial stone enterprises have demonstrated the advantages of their products surpassing natural stone by processing lengths exceeding 2 meters, with the longest even reaching 3 meters. This approach that disregards objective laws is wrong. Figures 12 and 13 show the granite lines processed by a well-known domestic artificial stone enterprise. Because the length of the line reaches 3 meters, and the thickness of the line is too thin, it can be seen from the picture that the line is severely deformed and completely bent.

The length and thickness of a line are closely related to its strength and thickness. It is easy to infer the relationship between the formulas in 1 and 2 in the article. When the length L of the line is longer, the same section of the line is subjected to greater stress. When the stress is greater than the ultimate stress that the stone can withstand, the line will break; Lines with the same cross-section are more prone to bending. When the deflection reaches the allowable limit of the stone itself, the lines will deform, deform severely, and even break.

The thickness of the line in Figure 6 is only 10mm. Can a line with a length of 3 meters be processed without deformation?

Can the lines in Figures 7 and 8 be thin, long, and thin without deformation?

Although the lines in Figures 10 to 12 have been widened, their contribution to the strength and deflection of the lines is not significant, and their effect is not significant.

“

03

The reasons for line deformation

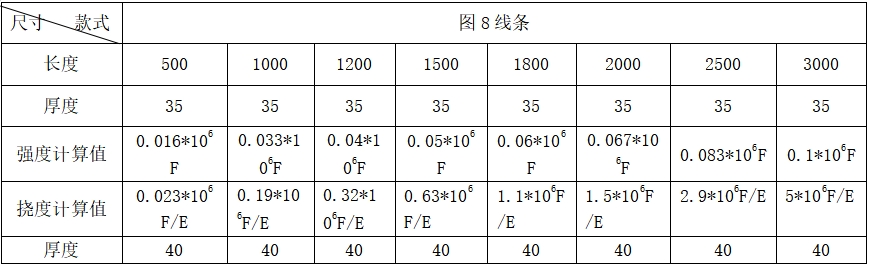

The main reason for line deformation is due to the length being too long and the thickness being too thin. The relationship and mutual influence between stress and deflection can be explained through the techniques of stress and deflection of the three lines in Figures 6 to 8.

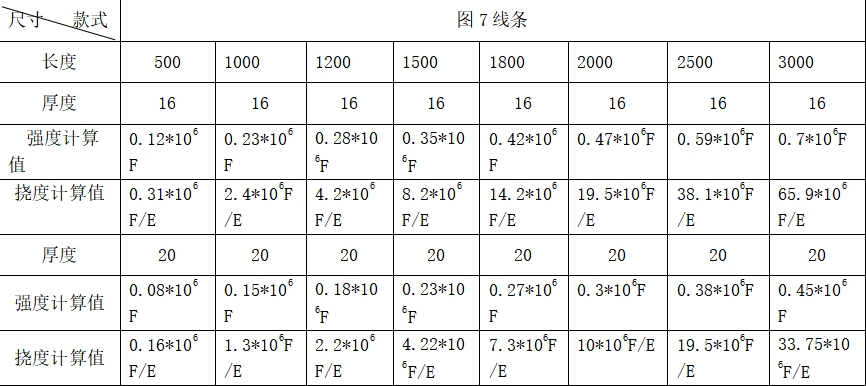

Stress, deflection, length, and thickness calculation Table 1:

Stress, deflection, length, and thickness calculation Table 2:

Stress, deflection, length, and thickness calculation Table 3:

The conclusion drawn from the three tables is that as the length of the line increases, the strength and deflection values of the line increase; As the thickness of the line increases, the strength value of the line decreases, and the deflection value also decreases.

Of course, there are many factors that affect the deformation of stone, which will not be discussed in this article.

“

04

How to prevent line deformation by lengthening

(1) Increase the thickness of the lines

When the length of the line increases, the thickness of the line should be increased to ensure that the line is not subjected to too much bending stress and does not undergo significant deformation.

(2) Reduce the length of the line

As stone enthusiasts know, the longer the length of a circular arc board or a circular arc irregular board, i.e., the fewer pieces it has, the longer the chord length of the circular arc board or circular arc irregular board, and the more likely it is to deform. Increase the number of segments and reduce the length of the lines to ensure sufficient strength and minimal deformation. This principle is also followed for curved lines. The length of the lines in Figure 15 varies, which can adapt to the stress and deflection values under different installation environments and conditions.

The arch lines in Figures 16 and 17 can be divided into 2, 3, and 4 sections, or they can be integrated as a whole. The overall decorative effect is the best, but there may be risks of line deformation and breakage. From the photo, it can be seen that the arch line is processed in two sections.

Figure 18 shows the lines of Van Gogh, with shorter segments estimated to be around 1 meter in length from the image. The reason why it is so short is due to the thin lines and the loose material of Van Gogh gold, which is prone to breakage.

(3) Reinforcement of lines

For some easily deformable and long lines, reinforcement with steel bars with a diameter greater than 6mm can be used along the length direction of the line to increase its strength and reduce deformation.

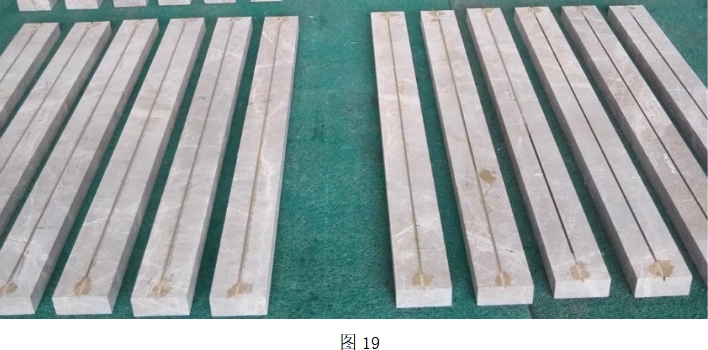

(4) Choose appropriate stone processing lines

For many years, the length of the granite line has reached 3 meters. If the thickness of such a long line is between 16.5mm and 30mm, it is easy to deform, as shown in Figures 12 and 13 in the text. Therefore, when the length of the granite line is long, the thickness of the granite should be increased. If the thickness of the line is not increased, the length of the line is reduced.

(5) Using composite processing technology to increase the strength of lines

If there is no thick material processing for long lines, composite processing can be used to increase the thickness of the lines to improve their strength, increase their stiffness, and reduce their deformation. Figure 20 shows the use of aluminum honeycomb composite panels to increase the strength of the lines; Figure 21 shows the processing of lines using three 20mm boards stacked and composite.

(6) Glue the lines onto the bottom plate

The thin, long, and thin lines in Figure 22 are bonded to the bottom plate, which can protect the thin and long lines from deformation and breakage.

(7) Properly place slender lines

It is important to place slender and thin lines. Placing too much, the lower lines are prone to deformation and breakage under pressure; The line placement method in Figure 23 is very good. The two lines are tied together to increase the thickness of the lines, ensuring that the lines do not deform or break during transportation, and the number of layers placed is only 2; Figure 24 is separated by lines with spacers to cushion the impact of the lines during transportation, making it easier to protect the lines from strong external forces; The thin and long lines in Figure 25 have too many layers placed, reaching 8 layers, and the lines are noticeably deformed.

Post time: Jun-09-2024