one 1、 The Evolution Process of Curtain Wall “T” Hangers

In the early development stage of stone curtain walls in China, T-shaped pendants, steel pins, and other components were usually used for hanging stone curtain wall panels. These materials required the production of stainless steel plates, bars, and other materials. This gave rise to the early production of T-shaped pendants for curtain walls, which were made of stainless steel plates through processes such as drawing lines, cutting plates, and stamping. The materials used were all austenitic stainless steel, and the variety, specifications, and styles of the production can also be customized according to needs, basically meeting the installation needs of curtain walls.

With the increasing usage area of stone curtain walls in China, the amount of T-shaped pendants installed on stone curtain walls has also increased. In order to meet the actual needs of use, many businesses have emerged that produce welded stainless steel T-shaped pendants and cast T-shaped pendants.

Welding stainless steel T-shaped pendants is made of stainless steel plates according to the sales specifications, using processes such as drawing lines, cutting plates, and welding. This type of component is usually welded with stainless steel plates of different thicknesses, and the welding parts are not easy to melt and weld, which is not easy to ensure the service life;

Cast T-shaped pendants are generally made of iron ore materials according to sales specifications, and are processed through manufacturing molds, melting, surface galvanizing or spraying. Generally, the surface treatment is not smooth and flat, and rust spots are prone to appear after use, reducing the service life.

two

Analysis of the Non Independent Disassembly and Assembly of Stone Blocks for the Installation of T-shaped Hangers

Front elevation view of stone curtain wall installation

Back elevation view of stone curtain wall installation

From the exterior and interior elevation views of the stone curtain wall installation, we can clearly see that this is a stone curtain wall installed using T-shaped fittings. According to the exterior and interior elevations, the stone panels are installed in a bottom-up order, with T-shaped fittings installed between the gaps between the stone panels. Using the hooks bent, welded, or cast at the front of the T-shaped fittings, a single T-shaped fitting needs to hook two pieces of stone at the same time.

Firstly, adjust the positioning of the next layer of stone. After determining the position, fill the installation groove with epoxy resin adhesive, and then install the T-shaped pendant. After adjusting the gap, flatness, and horizontal height of the T-shaped pendant of the stone plate, tighten the stainless steel fixing bolts to ensure firmness. When the horizontal gap is the same, further repair the epoxy resin adhesive in the installation groove of the stone to make it smooth and dense.

In this order, each panel of the stone curtain wall is installed according to the program. Therefore, if one of the stones needs to be replaced or removed after installation, it will be very difficult. Unless the top panel needs to be removed, it needs to be removed one by one from top to bottom until the position of the stone that needs to be replaced is reached.

three

The hidden danger of self weight accumulation caused by the installation of T-shaped pendants on stone curtain walls

1. Not applicable to building curtain walls:

For a high-rise building, the required decoration and renovation time is generally around 3-6 months (180 calendar days). For stone slabs, it takes about one month to prepare the raw materials until the finished products are ready to be supplied. If the area involved in stone curtain walls is relatively large, the supply cycle for individual stones is about one month.

Through this situation analysis, we often need to follow a segmented construction sequence from bottom to top during the actual construction of stone curtain walls in buildings. It is impossible for a single construction team to complete it from bottom to top. In this case, the construction period used cannot guarantee the expected decoration time of the construction unit. Therefore, it is generally divided into two or more construction teams to complete their respective work in sections from bottom to top. As a result, there will be a circle of stone blocks along the horizontal position of the building that cannot be installed between the two connected construction teams.

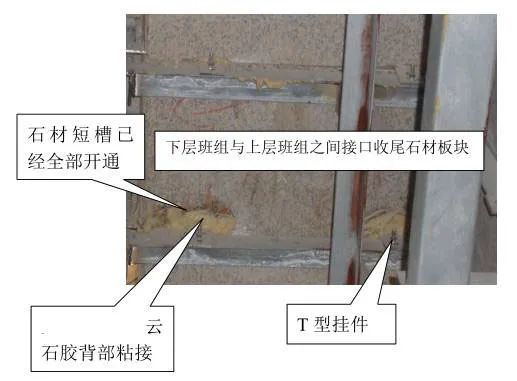

As shown in the above figure, this is a common method used for the installation of stone panels. Almost all stone curtain walls are installed from bottom to top by the lower team to the starting position of the upper team. The remaining circle of interface stones is made using the method shown in the above figure. The lower short groove of the stone panel is fully opened, and all short grooves of the entire panel are filled with stone marble adhesive. The upper short groove of the stone is inserted into the T-shaped pendant, and the lower short groove is quickly bonded with marble adhesive.

This approach overlooks a key issue, which is that marble adhesive is a pure structural material used for short-term and short-term temporary fixation. It is brittle and hard, and cannot be used as a material for long-term structures. Under long-term stress conditions, it can easily fracture, posing a safety hazard.

In addition, there is another characteristic that marble glue may fail in a short period of time when it encounters a series of humid water vapor states such as condensation water, and the stone plate itself has a certain degree of water permeability. Both marble and granite have this characteristic. Some stone plates have been protected according to the requirements, but they cannot be completely in place. After all, this is an artificial work process, and there may be more or less water seepage. Therefore, in a long-term state, there is a possibility of fracture between marble glue, stone, and hanging parts, which poses a safety hazard.

2. Stone slabs do not have complete independence:

A stone curtain wall that has undergone completion acceptance, when viewed from the outer surface, is very beautiful. The gaps between the panels, which are sealed with weather resistant sealant, reflect the beauty of each stone block.

However, we have overlooked the unimaginable problem of penetrating deep into the rear of the weather resistant sealant between the blocks, which is reflected one by one. It appears that the independent stone blocks are only surface phenomena.

Due to the fact that stone curtain walls are mostly made of welded steel keel made of Q235 material, and all the keels are formed by cutting, processing, manufacturing, and installation on the construction site, the installation of the keel for stone curtain walls is not perfect. Perhaps only the surface acceptance procedure tells us that it meets the requirements of relevant specifications. However, regardless of the quality of the installation of the keel for stone curtain walls, it is necessary to ensure the appearance of the external decorative panel, which brings certain difficulties to the installation of stone panels. The installation personnel of stone panels can no longer adjust or repair the installation deviation of the stone keel. In addition, the delivery and acceptance period of the external decoration also does not allow them to do this work. There is no channel to choose from, and only their own methods can be used. Go install the stone slab.

As shown in the actual picture above, in order to maintain a uniform horizontal gap between the stone blocks, stainless steel nuts and flat pads are placed between the gaps between the upper and lower stone blocks. Due to the gap between the short groove position of the stone blocks and the T-shaped pendant, the upper block of the T-shaped pendant is not completely supported by the T-shaped pendant. Therefore, theoretically independent blocks are used, but in reality, there is no independent block

As shown in the actual picture above, in order to firmly fix the stone slab, the T-shaped pendant originally installed on the upper part of the horizontal keel has now to be installed on the lower part of the horizontal keel, and stainless steel nuts need to be used to lower and tilt it, changing the normal stress state of the T-shaped pendant.

It is not difficult to see from the actual pictures above that what should have been an independent stone panel has hardly met the actual requirements, completely changing the stress state of the stone panel itself, causing the stone curtain wall of a facade to change from bottom to top into a single piece of stone instead of many independent panels. In this way, if one of the stones has problems, or if there is a T-shaped pendant with problems, it will bring about problems with the stone of a facade.

Even if this assumption does not occur during use, compared to stability, if encountering an earthquake state where both longitudinal and transverse waves appear before and after, the installation method of this system will not be able to avoid the disaster of earthquakes.

four

Conclusion analysis of T-shaped pendant:

Based on the actual analysis in the previous section, the T-shaped pendants used in stone curtain walls can no longer meet the actual usage requirements and safety construction requirements. In order to create a beautiful and reassuring living and working space for people, our curtain wall industry must use detachable separated pendants. Only in this way can the sections of stone curtain walls truly achieve independence, while paying attention to the construction that meets seismic requirements.

five

The erroneous transformation from stone construction to porcelain plate construction:

With the diversification of building materials, combined with how to reduce the weight of the building structure, on the basis of the design of stone curtain walls, ceramic panels have been applied to building curtain walls. The application of ceramic panels to building curtain walls also requires attention to avoid the same structural and installation hazards as stone.

Schematic diagram of porcelain plate installation structure 1

Schematic diagram of porcelain plate installation structure 2

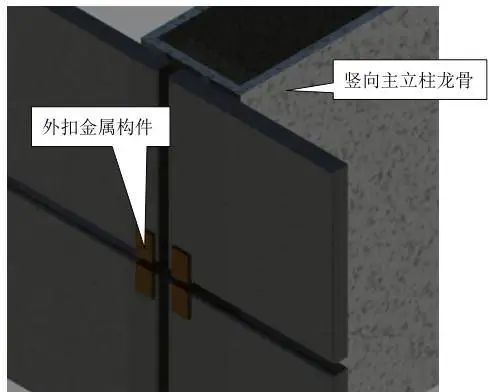

The above diagram shows the actual construction of a porcelain curtain wall, which uses L-shaped metal construction plates to fix the porcelain plate firmly from the outside of the plate. In other words, an independent porcelain plate plate plate is fixed by four metal L-shaped components, with hard metal pads used to fill between the L-shaped metal components.

From the illustration in this picture, it is not difficult to analyze that it actually evolved from the traditional T-shaped pendant for installing stone. Once the structure is formed, it is consistent with the actual installation of stone mentioned above, resulting in all ceramic panels being a whole ceramic panel from bottom to top. At the same time, the components are tightly fixed to the ceramic panels, and there is no mobility between the ceramic panels and the components. How can this ceramic panel achieve the requirement of being removable after construction and installation? In fact, this structure cannot be achieved at all.

From this, it can be said that ceramic panels and stone materials should have unified structural measures. Regardless of installation, they must meet detachable installation measures and seismic requirements.

Post time: May-20-2024